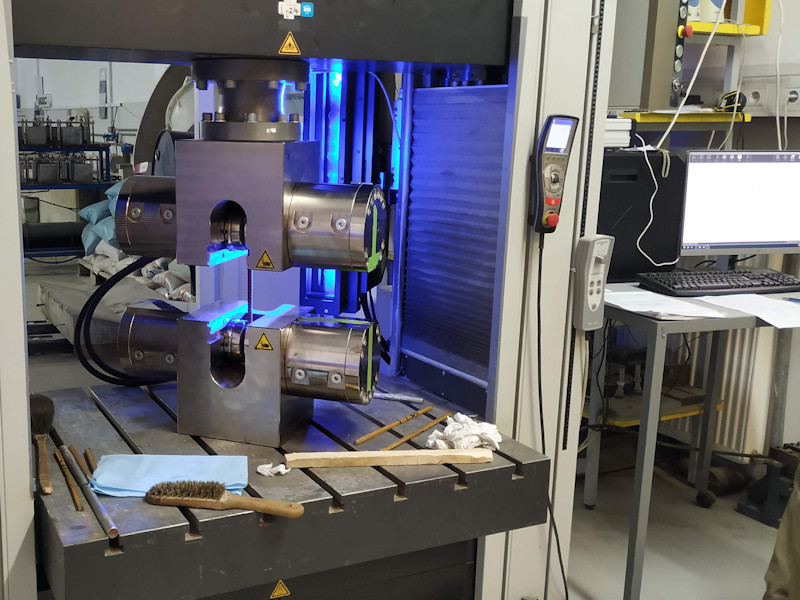

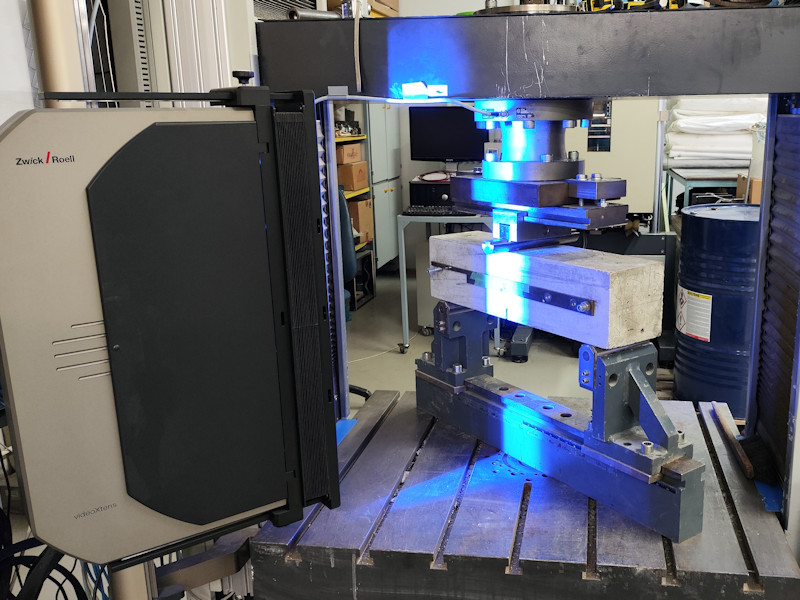

With its activity, LMPM is interwoven with all other departments of the institute, since in addition to internal calibration and checks of laboratory equipment, it performs mechanical tests related to measurements, which are mainly performed on the Zwick universal testing machine.

Mechanical tests

The Zwick universal testing machine enables precise measurements of displacements, forces, speeds, etc. The tests can be performed independently or as a final measurement on test specimens prepared by other laboratories.

The basic activities of the laboratory are:

- performing laboratory tests

- carrying out special and demanding tests prescribed in standards or according to individually requested procedures

- introduction of new tests into the properties of materials

- numerical modeling of material properties

- other as needed

Metrology

Setting up and checking the laboratory equipment is an important part of the operation of every analysis laboratory, since the proper functioning of the equipment enables the correct performance of laboratory tests. In addition to internal calibration and checks, the laboratory also performs calibration of laboratory equipment for external clients.

LMPM takes care of managing the database in connection with the planning and implementation of calibrations and checks of laboratory equipment. Records of all performed internal and external calibrations and checks are kept in the database.

The physical quantities that the metrology laboratory calibrates and checks are:

- time

- dimensions

- mass

- force

- displacement

- temperature

- relative air humidity

- pressure, underpressure, overpressure